Cutting-edge Robotic Pallet Storage Automation

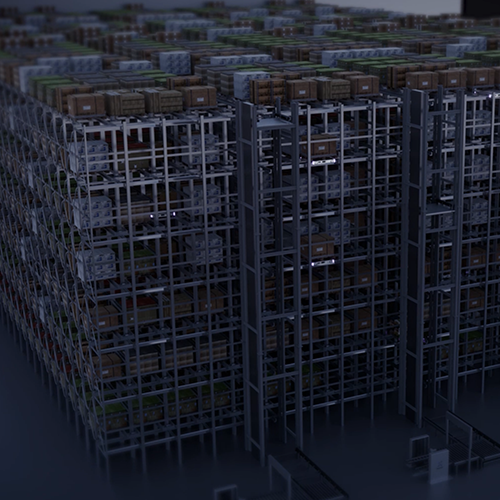

Unlike traditional elevators, XCube uses bi-directional vertical shuttles that can be placed in any aisle, delivering unmatched design flexibility and eliminating throughput bottlenecks.It is especially suitable for compact spaces with high storage requirements, such as buffer-area pallet storage or line-side pallet storage.

For warehouses around 1,000 m², XCube provides a tailor-made high-density storage solution that maximizes space utilization. with XCube can double the storage capacity of the existing warehouse, dramatically reducing costs.

With customizable pallet and robot configurations supporting loads of up to 2 tons. Its wide temperature range from -25°C to 45°C also makes it perfectly suited for cold storage applications.

Redefining High-Density Pallet Automation - From Inbound to Outbound

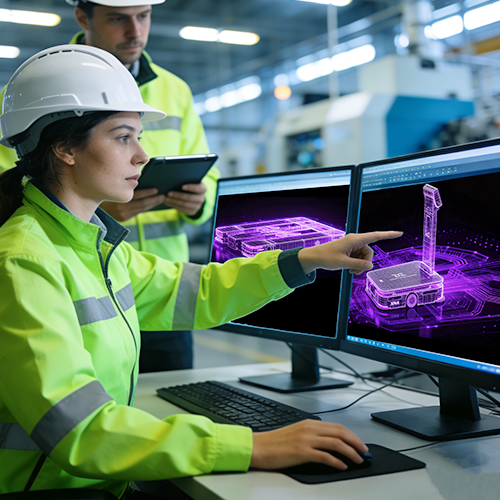

By combining the XMove inbound and outbound automation system with the XCube storage solution, NovaX Automation delivers a truly end-to-end unmanned warehouse workflow capable of operating 24/7 without interruption.

The XMove system minimizes human error, boosts throughput, reduces dependency on manual labor, and significantly lowers operational costs while easing workforce pressure. With its real-time visualization and monitoring features, warehouse managers can oversee processes remotely and respond quickly to any changes — enabling truly autonomous 24/7 warehouse operations.

1-1.5 Years ROI

Quick ROI

NovaX Automation solutions deliver measurable value fast — achieving a full return on investment within just 1 to 1.5 years

Minimize Human Errors

NovaX Automation solutions minimizes human errors and lowers warehouse space and management expenses through standardized, controllable processes

With the right balance

Between performance and cost, NovaX Automation provides a highly competitive total cost of ownership

Quick & Simple Installation

NovaX Automation solutions are designed to eliminate one of the biggest concerns for warehouse operators: costly and disruptive reconstruction. Instead of requiring extensive structural changes, our systems have low floor requirement and are built to seamlessly integrate into existing warehouse operations.

Thanks to their modular and plug-and-play design, NovaX Automation solutions can be installed rapidly, minimizing downtime and allowing automation to start delivering value almost immediately. Customers can choose to begin with entry-level or partial automation, targeting repetitive processes first, and then gradually expand to full end-to-end automation — all without disrupting ongoing operations.

Unlike many traditional systems that require multiple hardware and software interfaces — often error-prone and complex — NovaX Automation ensures a streamlined, user-friendly integration that reduces risk, lowers training requirements, and accelerates go-live.

Whether used for pallet storage, order picking, or full warehouse automation, NovaX Automation solutions deliver fast implementation, reliable performance, and rapid productivity gains — providing customers with a simple, powerful path to future-ready logistics.

Local Service & Support

France

France

Germany

Germany

California

California

Contact Us

NovaX Automation

Under NovaX Robotics Group Contact NovaX Automation experts and learn how we can optimize the pallet storage density and enable a higher efficiency.

Address

NovaX Robotics GmbH

Prinzenallee 7, 40549 Düsseldorf

info@novaxautomation.com

Phone

+49 21152391000