XPPS SMART WAREHOUSE SOFTWARE

NovaX Automation “Smart Brain” of Pallet Warehousing. Full Control in One Click.

XPPS — Pallet warehousing’s intelligent core. XWES + XRCS + data & simulation. Advanced algorithms. Modular design. Full-process resources, optimized effortlessly.

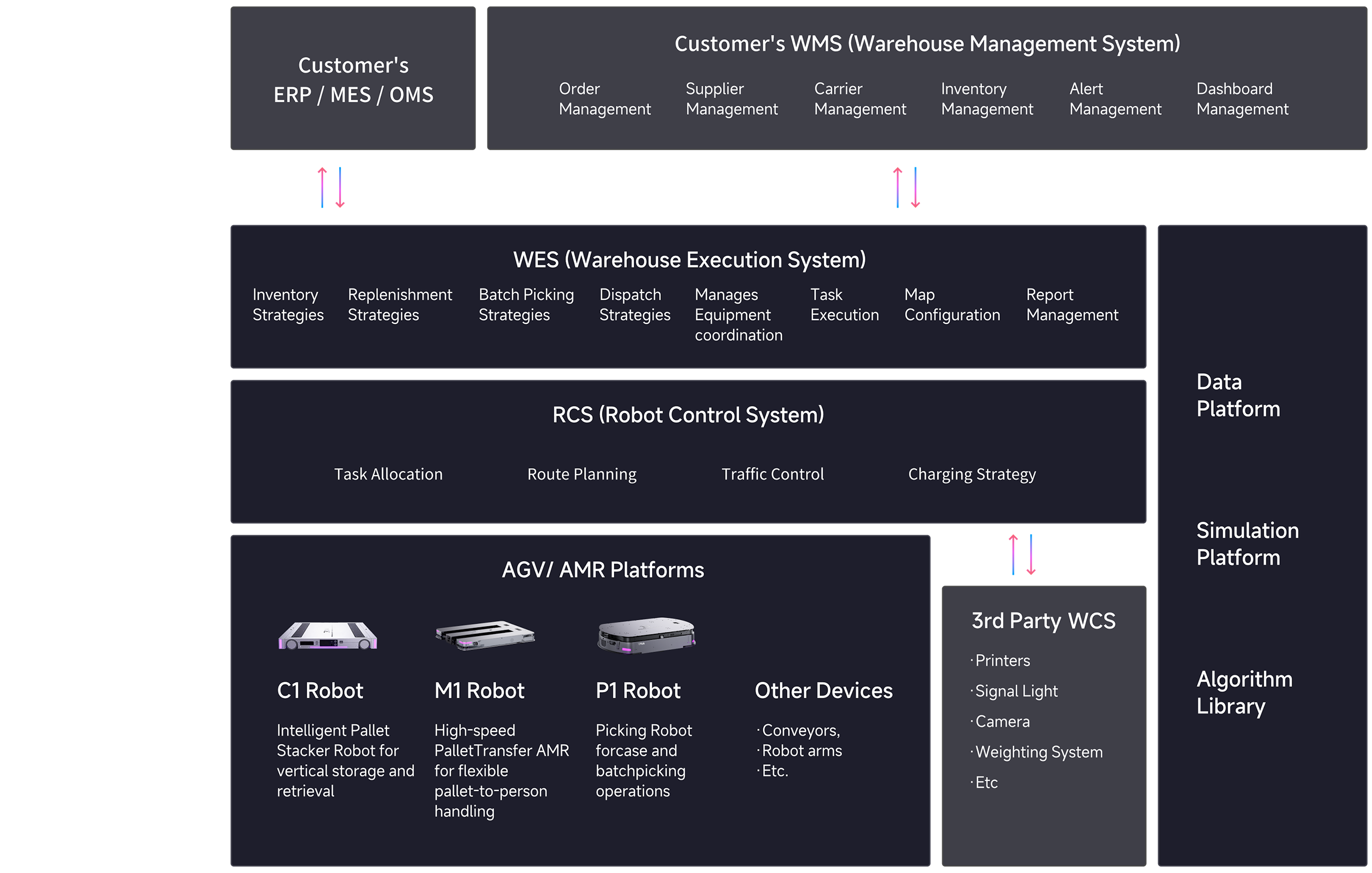

Software Architecture

Product Advantages

Easy Configuration

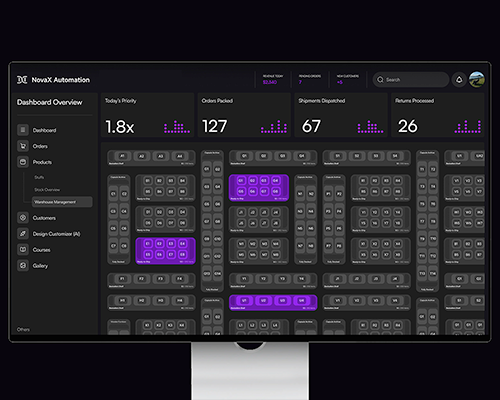

Intuitive graphical interface simplifies AMR mapping, path planning, and work zone setup(for XPick P1 and XMove M1 robot).

Flexible Orchestration

Enables dynamic workflow coordination across manufacturing, logistics, and warehousing scenarios.

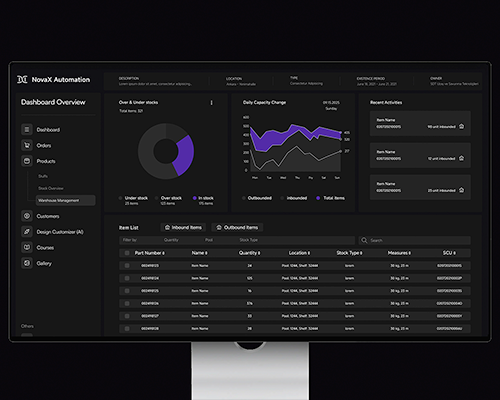

Real-Time Control

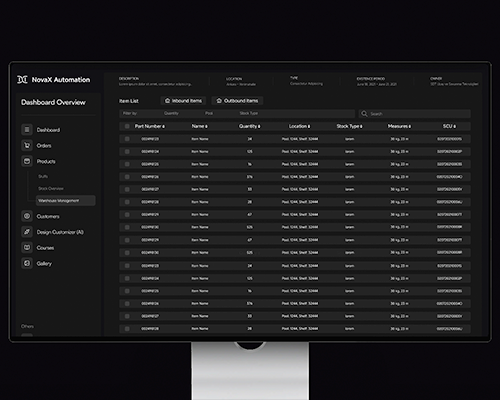

Provides live monitoring and rapid response to ensure efficient execution and full operational visibility.

Seamless Integration & Optimization

Open API connects smoothly with business systems for task allocation, resource scheduling, and path optimization, enhancing efficiency and reducing labor costs.

XPPS

Pallet-To-Person Intelligent Warehousing Software

XPPS is the central intelligence behind NovaX Automation’s end-to-end robotic ecosystem — a unified platform that connects every robot, process, and data flow in the warehouse. Built on a modular architecture, it integrates the WES (Warehouse Execution System), RCS (Robot Control System – available in Basic, Standard, and Professional versions), and a real-time Data & Simulation Platform.

Together, these modules create a cohesive, flexible, and scalable control system that enables full automation across inbound, storage, picking, and outbound processes.

XWES

Intelligent Warehouse Execution System

A high-efficiency warehouse execution system designed for automated order processing.

Built on a modular architecture, XWES seamlessly integrates various containers, robots, and workstations to enable intelligent operations such as storage, retrieval, transportation, picking, and sorting.

The system automatically recognizes the operational characteristics of both automated and conventional warehouses, as well as the real-time status of equipment, to dynamically select the optimal storage strategy and efficiently coordinate all resources — greatly enhancing overall warehouse performance.

XRCS

Intelligent Robot Scheduling System

The RCS is designed for multi-robot coordination within a shared workspace, ensuring smooth and efficient fleet operations.

Built on spatial modeling and collision detection algorithms, it enables advanced functions such as vehicle following, congestion detection, deadlock avoidance, and obstacle bypassing.

By leveraging a time–space window heat map algorithm, the system predicts robot positions across both spatial and temporal dimensions, enabling high-efficiency path planning and intelligent charging management — achieving optimized, safe, and coordinated multi-robot operations.

Contact Us

NovaX Automation

Under NovaX Robotics Group Contact NovaX Automation experts and learn how we can optimize the pallet storage density and enable a higher efficiency.

Address

NovaX Robotics GmbH

Prinzenallee 7, 40549 Düsseldorf

info@novaxautomation.com

Phone

+49 21152391000