XCube C1

Four-Way Pallet Shuttle

Key Features

The XCube C1 Four-Way Shuttle is an intelligent pallet storage robot designed for next-generation high-density pallet storage systems.

With four-directional movement, autonomous handling, and multi-vehicle collaboration, XCube C1 delivers high flexibility and precise space utilization, maximizing warehouse capacity through vertical pallet storage.

It integrates seamlessly with elevators, conveyors, robotic arms, and other automation equipment, making it adaptable to a wide range of high-density storage scenarios across industries

-25 ℃

Min temp+45 ℃

Max temp2,000 kg

Max loads carried

1.6 m/s

Max speedXMove M1

Next-Generation Pallet Handling AMR

Key Features

The XMove M1 Pallet Handling Robot combines the strengths of traditional forklift AMRs and low-profile AGVs into a single, versatile solution. Featuring a compact, under-ride chassis integrated with fork arms, the XMove M1 achieves the agility of a tugger vehicle while directly lifting and carrying pallets.

This design eliminates the limitations of standard forklifts—such as large turning radii and slow maneuvering speed—while offering a more flexible alternative to conventional AGVs that require extra racking. The XMove M1 delivers efficient, space-saving, and fully automated pallet transport across diverse logistics and warehouse scenarios.

1.8 m

Narrow aisles

8 h

Battery endurance1,000 kg

Loads carried

1.8 m/s

Max speedXPick P1

Collaborative Robotic Picking System

Key Features

The XPick P1 is an intelligent picking robot designed to revolutionize traditional warehouse operations. By replacing manual cart movement with autonomous pallet-handling robots, XPick P1 streamlines order fulfillment — boosting efficiency, accuracy, and ergonomics for operators.

With deep-learning computer vision, XPick P1 robots don’t just detect — they understand. They can recognize people, forklifts, pallet jacks, other robots, and goods, ensuring safe, adaptive collaboration in dynamic warehouse environments. Delivering up to 60% labor savings and ROI within one year, XPick P1 enables a faster, smarter, and more human-centered approach to warehouse picking.

1,240×830 mm

Max load surface

8 h

Battery endurance1,500 kg

Max loads carried

7 Sensors

LiDAR+UWA Cameras + 3D CamerasXPPS

Pallet-To-Person Intelligent Warehousing Software

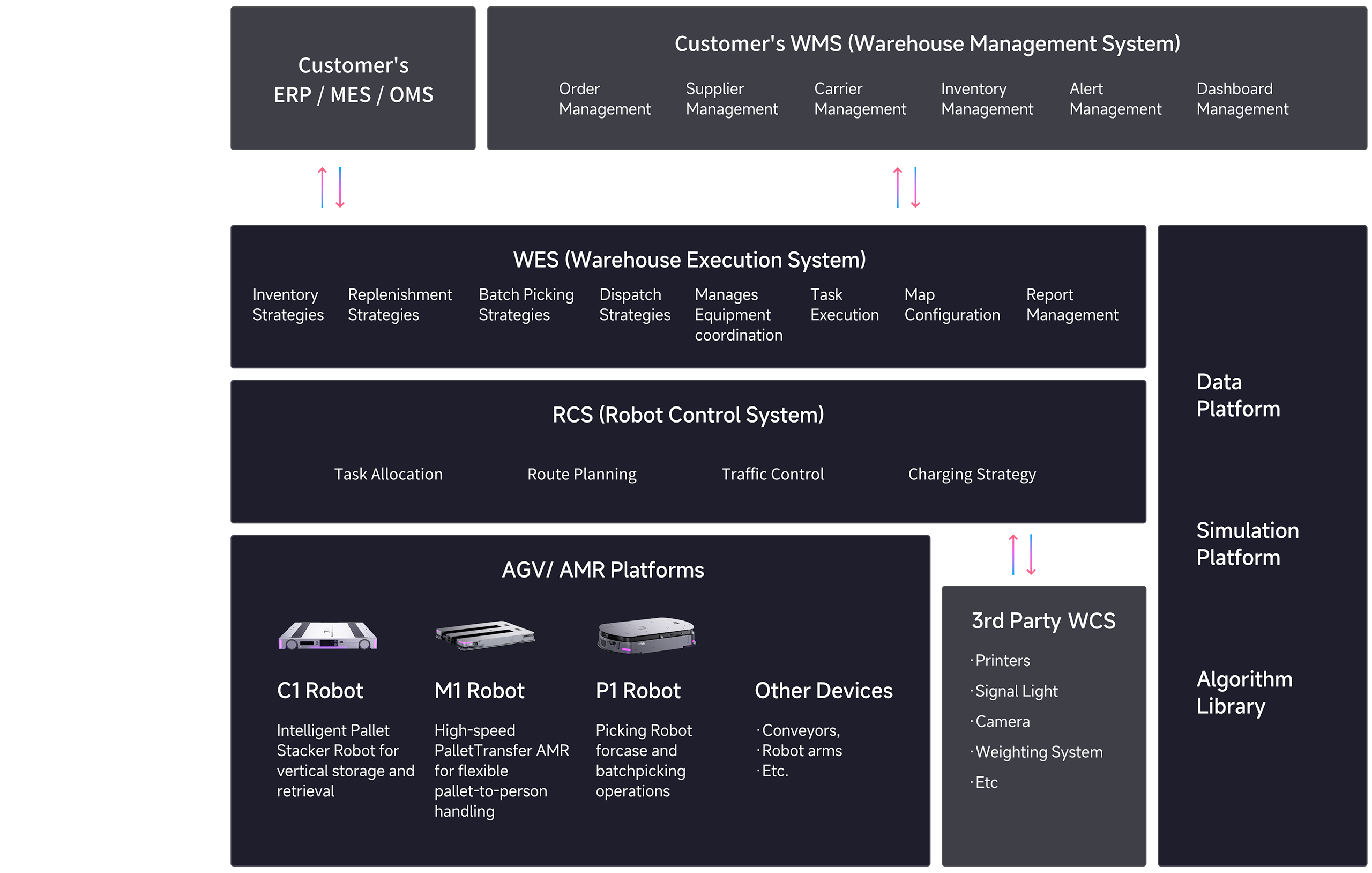

XPPS is the central intelligence behind NovaX Automation’s end-to-end robotic ecosystem — a unified platform that connects every robot, process, and data flow in the warehouse. Built on a modular architecture, it integrates the WES (Warehouse Execution System), RCS (Robot Control System – available in Basic, Standard, and Professional versions), and a real-time Data & Simulation Platform.

Together, these modules create a cohesive, flexible, and scalable control system that enables full automation across inbound, storage, picking, and outbound processes.

Contact Us

NovaX Automation

Under NovaX Robotics Group Contact NovaX Automation experts and learn how we can optimize the pallet storage density and enable a higher efficiency.

Address

NovaX Robotics GmbH

Prinzenallee 7, 40549 Düsseldorf

info@novaxautomation.com

Phone

+49 21152391000